OD 42-70mm wheels Dual/Triple Roller Traction Alloy Steel Wire Motor Wire Straightener Equipment

![]() φ42-18 Wheels+Triple Roller Traction Drawing.pdf

φ42-18 Wheels+Triple Roller Traction Drawing.pdf

![]() φ42-18 Wheels+Dual Roller Traction Drawing (2).pdf

φ42-18 Wheels+Dual Roller Traction Drawing (2).pdf

![]() φ54-18 Wheels+Triple Roller Traction Drawing.pdf

φ54-18 Wheels+Triple Roller Traction Drawing.pdf

![]() φ70-18 Wheels+Triple Roller Traction Drawing.pdf

φ70-18 Wheels+Triple Roller Traction Drawing.pdf

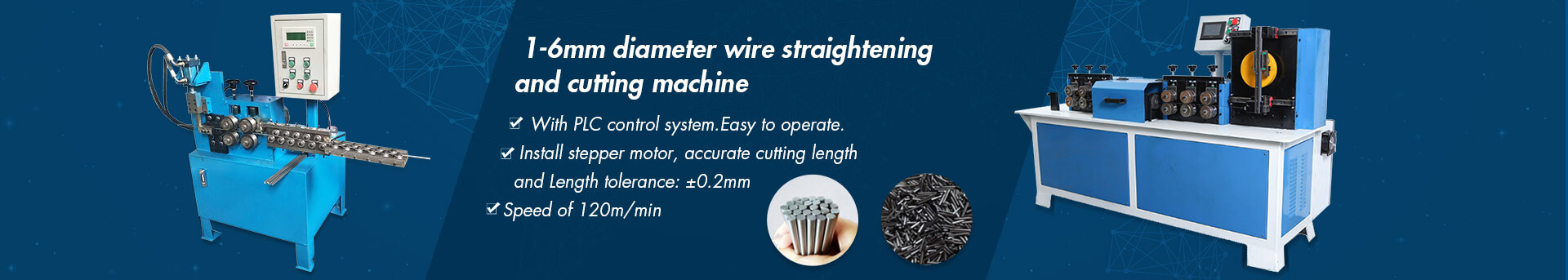

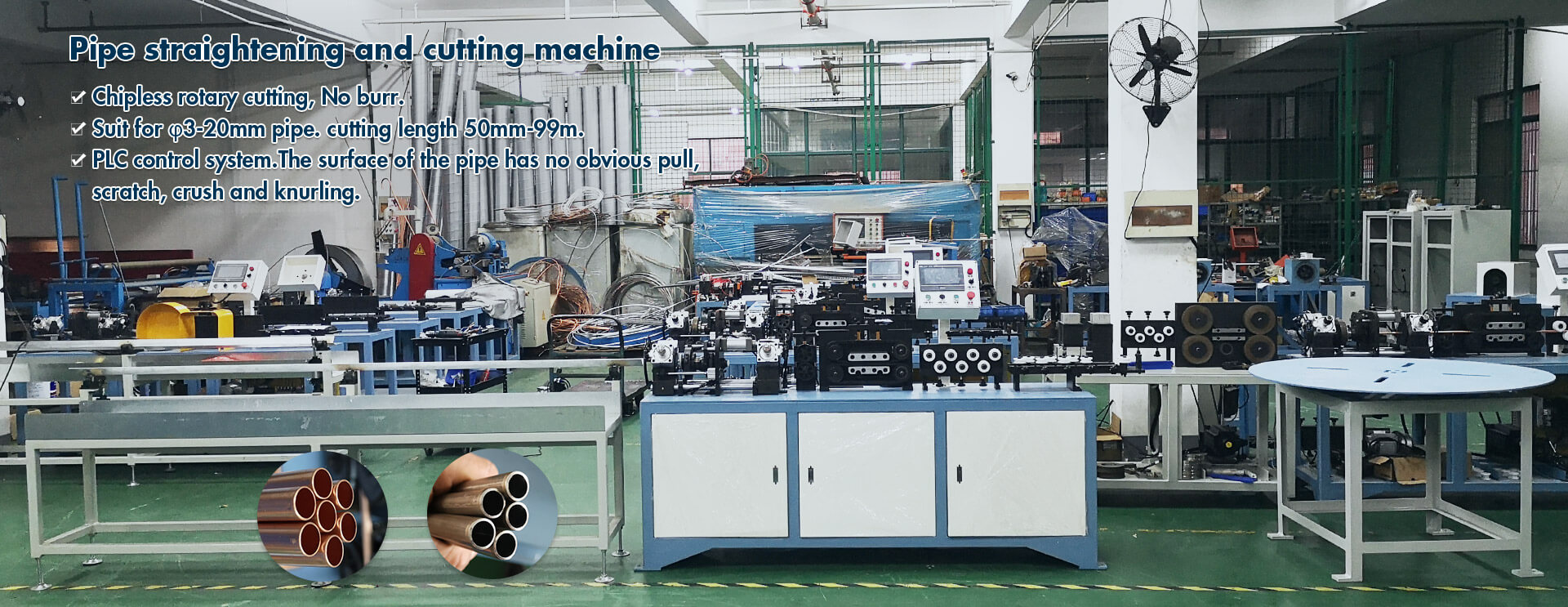

Shanghai Qi Pang mainly focuses on the production of : electric straighteners, manual straighteners, CNC straightening and cutting machines, and traction feeding systems.

Motor Wire Straightener Equipment are suitable for various materials, such as: copper/aluminum/stainless steel/iron wire and pipes, and are applicable to both round and square materials.

Our Motor Wire Straightener Equipment is widely used in wire drawing machines, metal wire processing industry, polishing machine,construction sites, refrigeration equipment and rewinding equipment, etc., and can efficiently straighten metal wires and pipes, thereby improving production efficiency.

Motor Wire Straightener Equipment is specialized equipment designed to straighten metal wire and tubing, primarily used to eliminate bending deformations caused during processing or heat treatment. By applying external force, it restores the workpiece to its ideal straightness or precision, ensuring the wire achieves the desired straightness.

The Motor Wire Straightener Equipment features diverse models and functions, offering high cost-effectiveness and easy adjustability. Since the rollers can be controlled via an adjustment mechanism, minimal maintenance is required. Additionally, you may opt to install digital position indicators on the straightening machine, facilitating roller adjustments by operators. These indicators record the specific adjustment positions of each roller, enabling reuse when processing wire of the same diameter in the future.

I. Motor Wire Straightener Equipment Parameters:

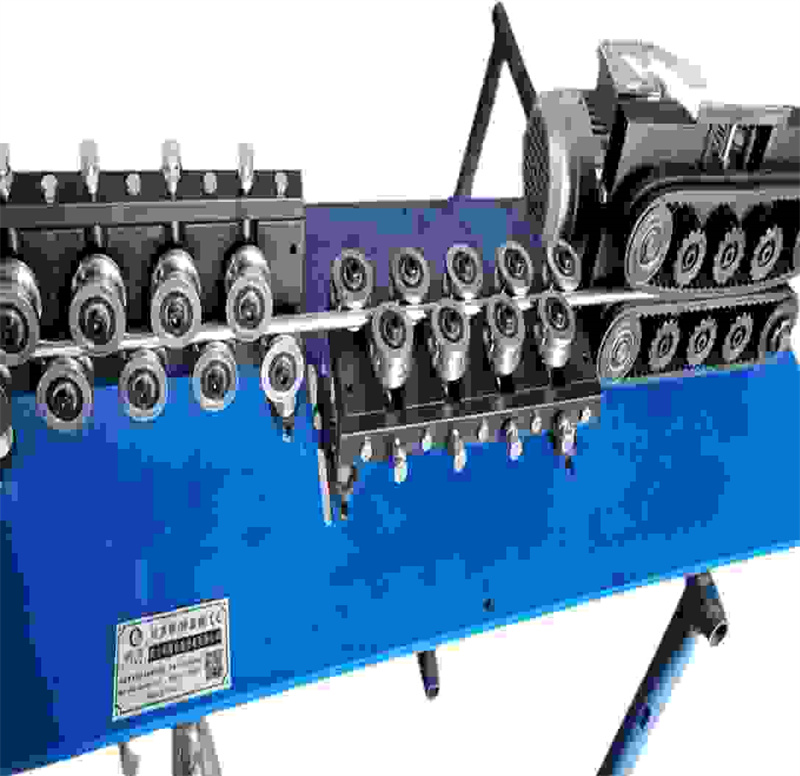

1.Style: ① Single-direction: All rollers are mounted on the same plane, arranged in two rows, top and bottom.

② Single-direction: Composed of horizontal and vertical straightening modules, offering a wider range of straightening surfaces and superior straightness.

2. Fixed with a base plate, and each wheel on top is adjustable.

3. Number of rollers: standard: Single direction 9 rollers or Horizontal + vertical direction 9 + 9 rollers

Customization available: ① Single direction: 5, 7, 9, 11, 13 rollers;

② Horizontal + vertical direction: 5+5, 7+7, 9+9, 11+11, 13+13 rollers

4. Roller outer diameter: 16mm/23mm/30mm/32mm

5. Traction: Roller drive (dual or triple sets optional; steel wheels/polyurethane wheels optional)

6. Upper row rollers are individually adjustable

7. Motor power: 0.55KW/0.75KW/1.1KW/1.5KW/3KW selectable

8. Power supply: 380V, three-phase, 50Hz

9. The frequency converter can be installed to adjust the machine speed

10. Speed : 8-10m/min(also can customized faster speed)

11. Rollers can be used for light or heavy-duty applications

12. Single-row ball bearings are suitable for wires with a maximum tensile strength of R = 600 N/mm².

Double-row ball bearings in hardened steel are ideal for wires with higher tensile strength, ranging from R = 600 N/mm² to R = 2200 N/mm²

13. Grooving: Standard "V" groove type. "U"/H groove type can be customized according to customer requirements

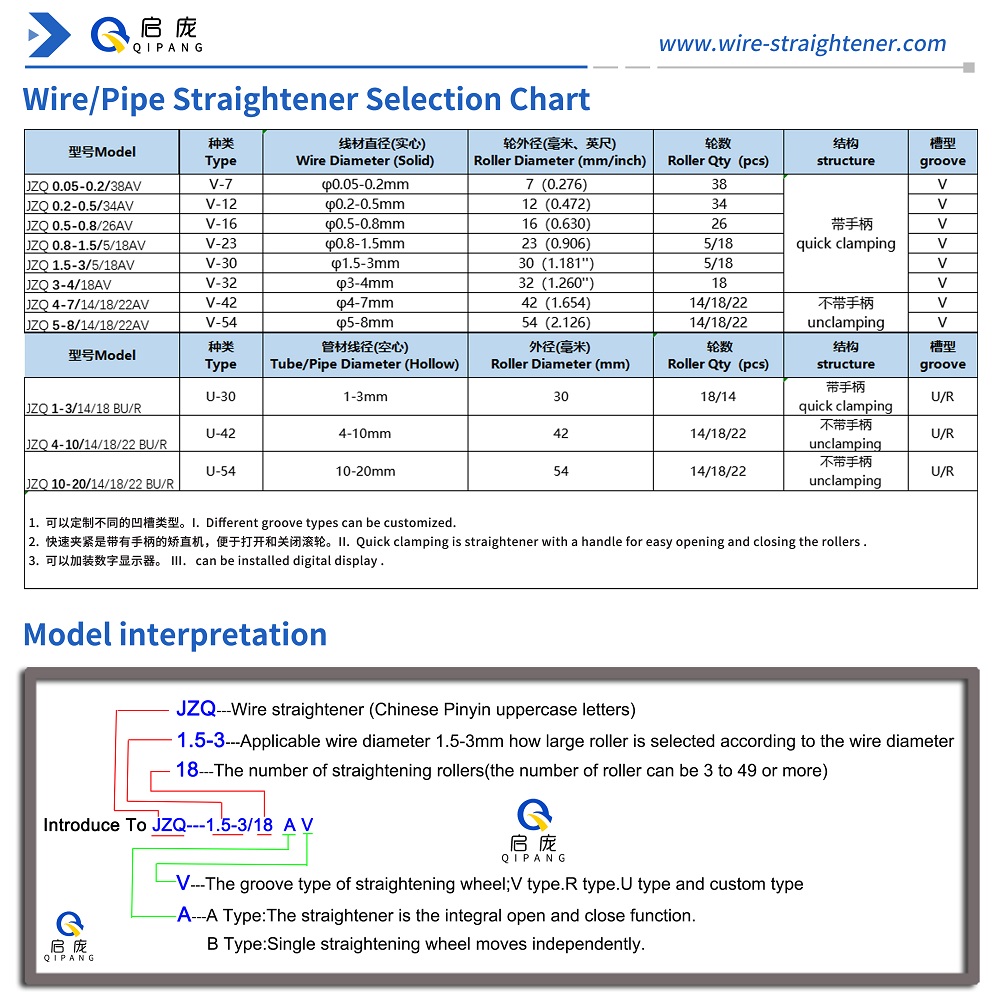

II. Motor Wire Straightener Equipment Diameter Selection Chart:

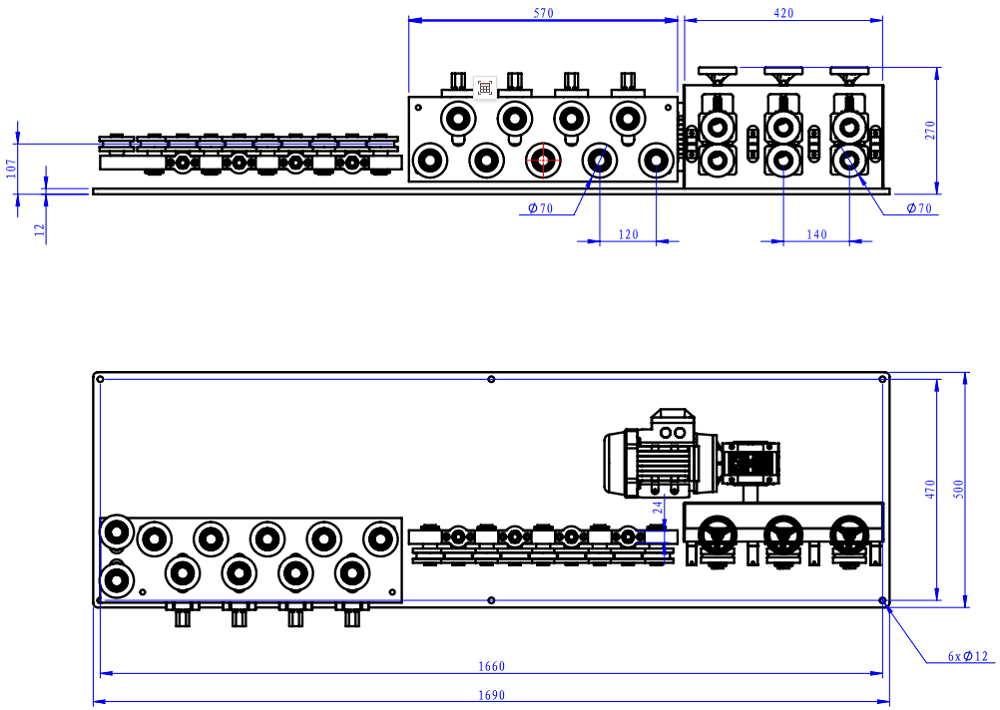

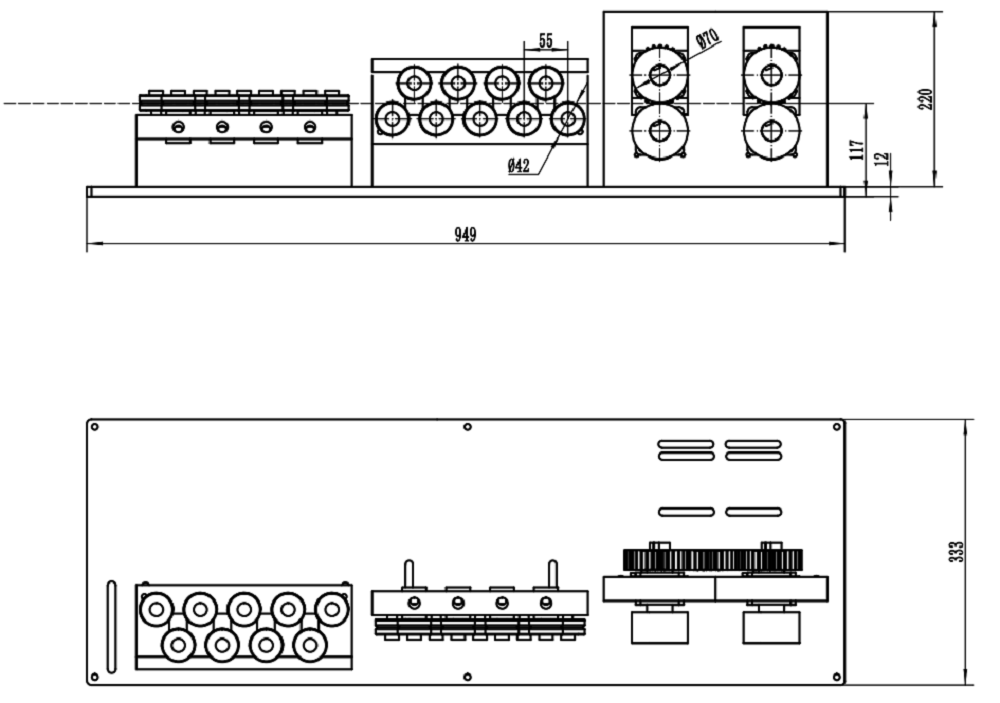

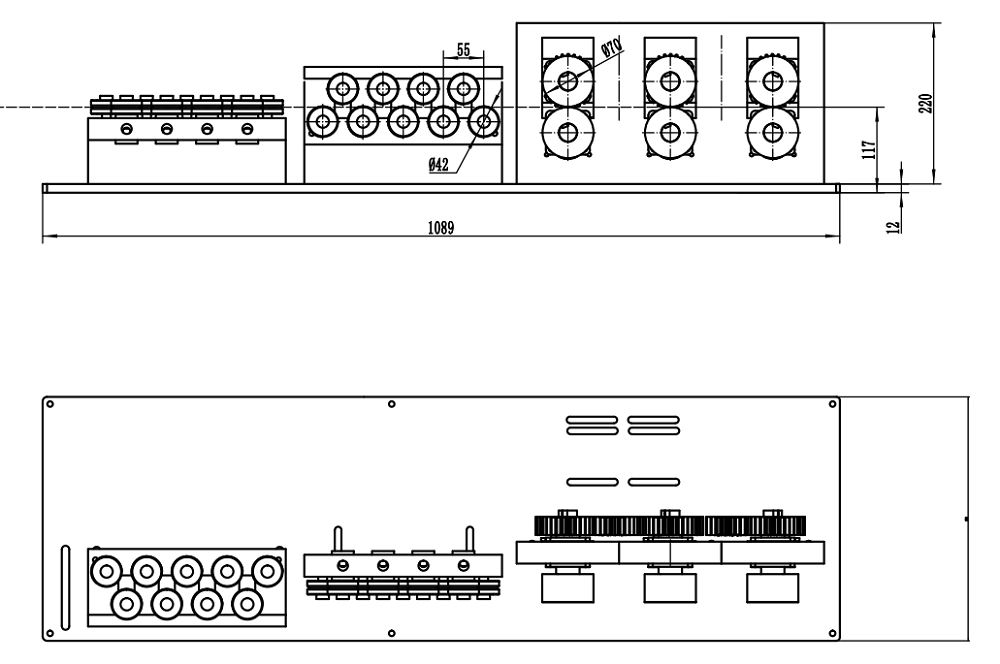

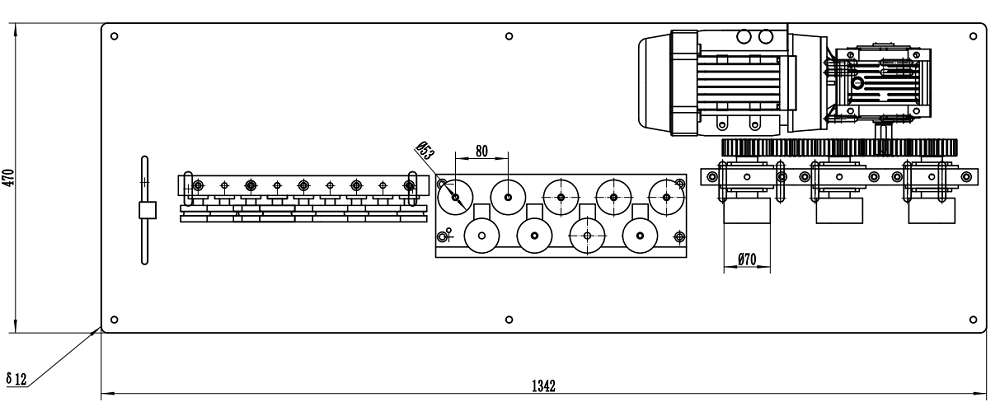

III. Motor Wire Straightener Equipment Drawing:

①φ42-18 Wheels + Dual Roller Traction

②φ42-18 Wheels+Triple Roller Traction

③φ54-18 Wheels+Triple Roller Traction

④φ70-18 Wheels+Triple Roller Traction