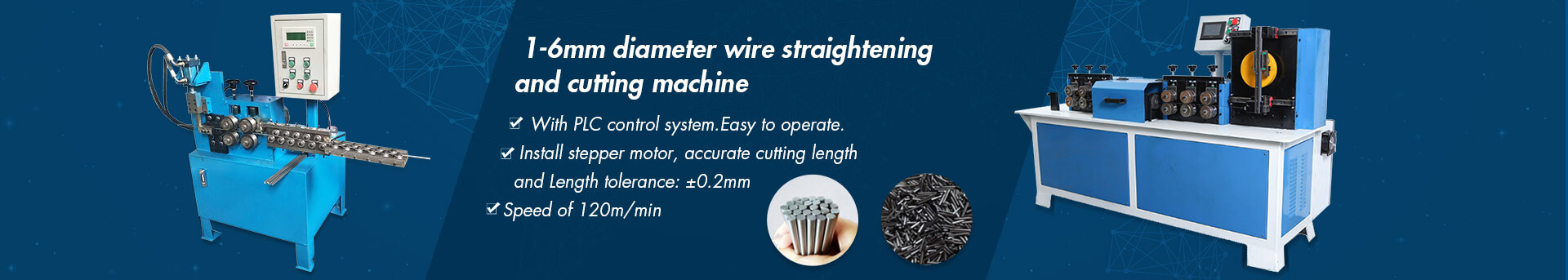

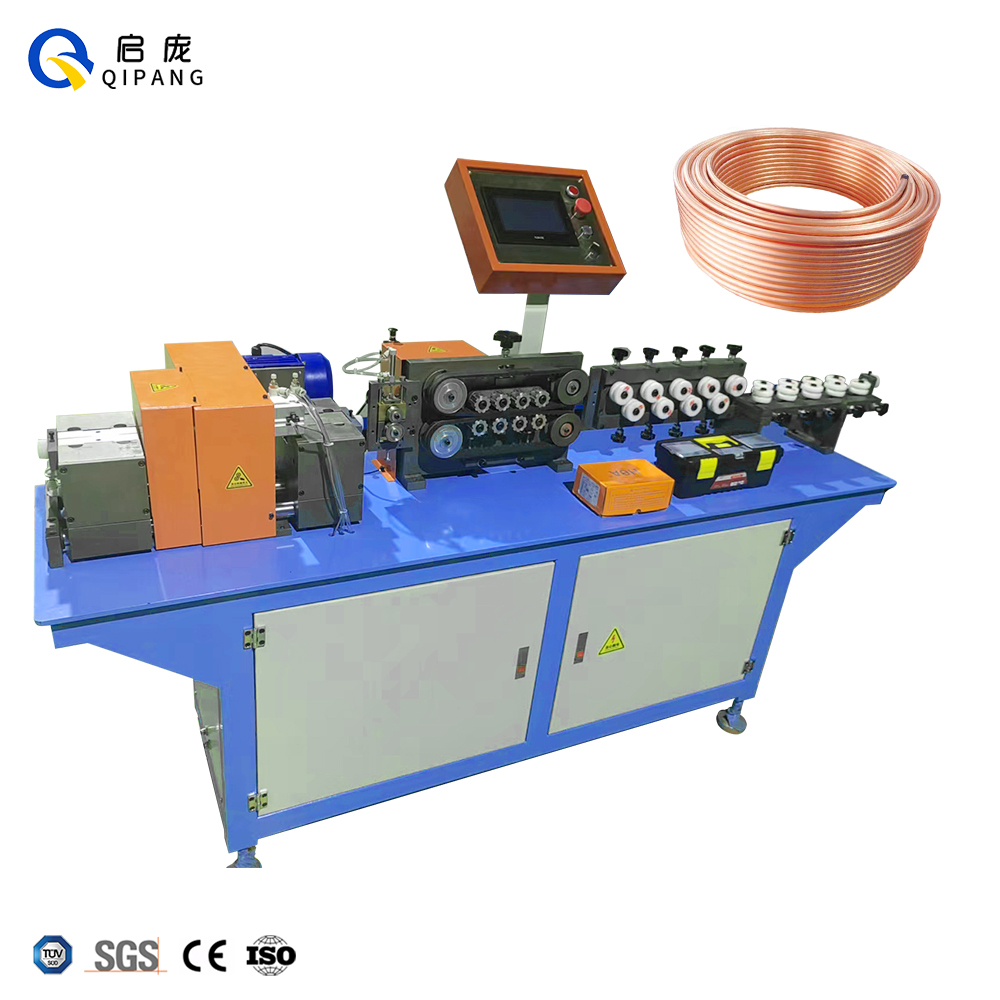

QIPANG Φ4-15.88mm 5/32''- 5/8'' Chip-free cutting Copper tube straightening and cutting machine

Shanghai Qipang mainly focuses on the production of : CNC straightening and cutting machines, electric straighteners, manual straighteners, and traction feeding systems.

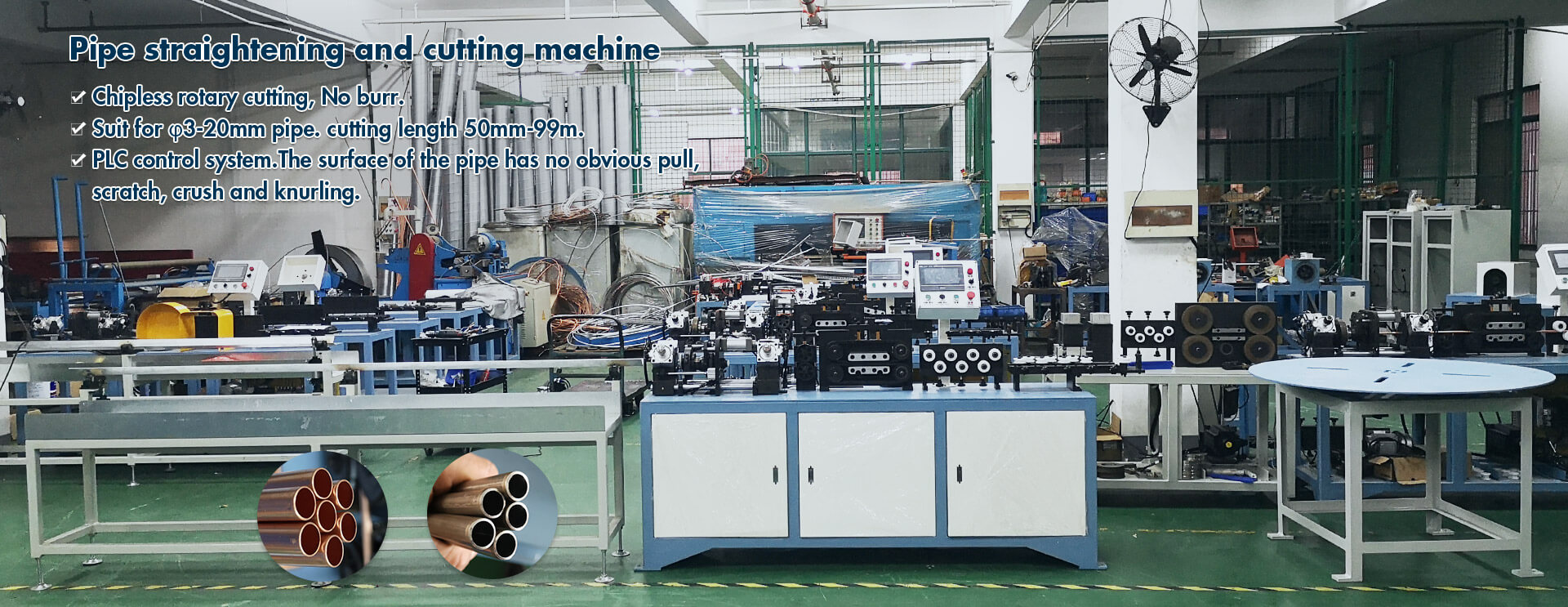

Copper tube straightening and cutting machines are suitable for various pipe materials, such as copper pipes, aluminum pipes, stainless steel pipes, Bondi pipes, and iron pipes, and are applicable to both round and square pipes.

Copper tube Straightening and cutting machines are suitable for pipe outer diameters of : 4 mm, 6.35 mm, 8 mm, 9.52 mm, 12.7 mm, 15.88 mm( 5/32",1/4",5/16",3/8",1/2",5/8").

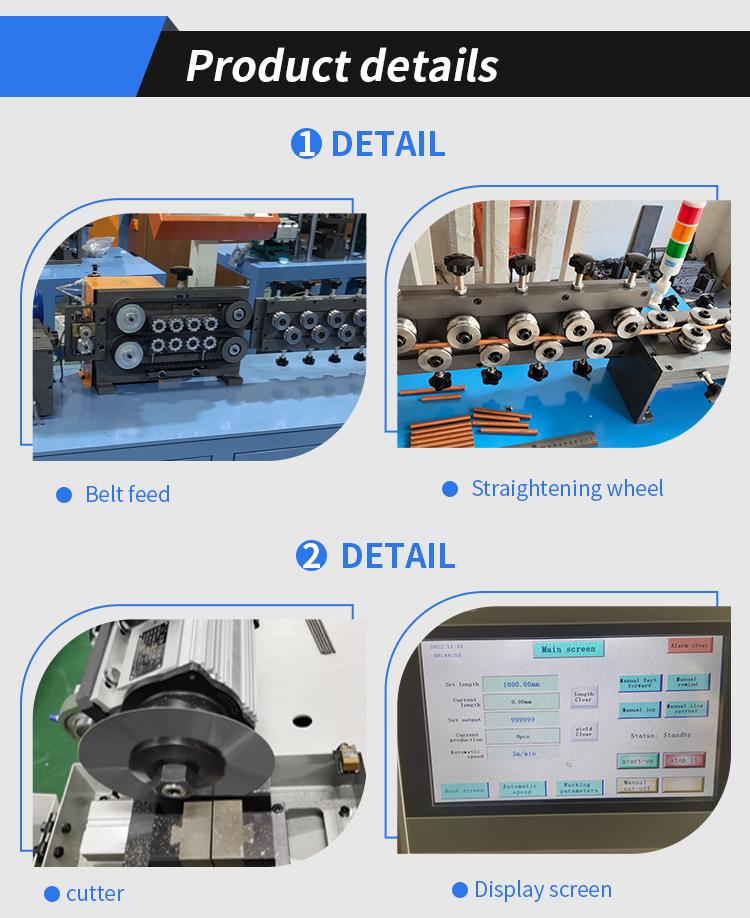

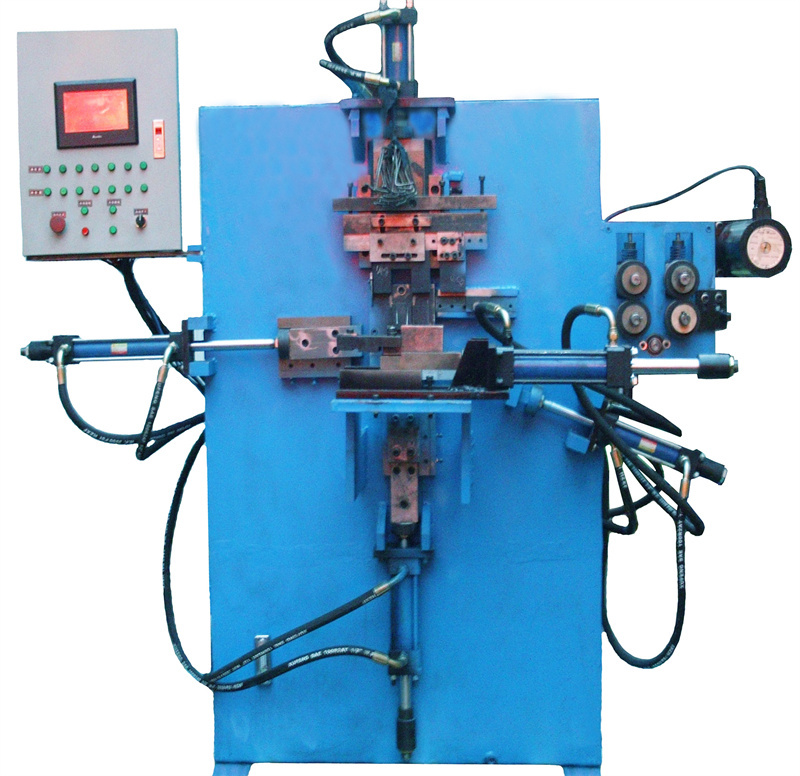

The Copper tube straightening and cutting machine adopts a PLC servo touch screen control system; the material is manually fed to the feeding rack, straightened by the horizontal and vertical straightening group, fed by the servo motor rotating the belt, the encoder counts the length, and then cut off.Our plant research and development of CNC three-section clamping die chip free automatic blanking machine is different from the traditional two-half jig steel tube cutting machine, drawing on the structural principle of the lathe head, the use of three-chuck jig, from three angles at the same time to apply the force. When replacing the fixture, there is no need to re-adjust the concentricity of the fixture, so the replacement process is more convenient. When the tube is pulled, the deformation degree of the tube is minimized to ensure the appearance quality of the tube.

The complete set Copper tube straightening and cutting machine includes:

1. Pay-off rack (multiple styles available)--Optional

2. CNC straightening and cutting machine (main unit)

3. Pneumatic tilting receiving rack (standard 1.2-meter length selectable)--Optional

Note: Unless otherwise stated, the quote usually only includes the main unit.

| Technical Parameter | |||||

Device model | Single head+Belt traction | ||||

| Applicable pipes | copper,aluminum,stainless steel,bondi pipes | ||||

| Pipe processing range | Φ4-Φ16 (Φ5/32''- 5/8'') | ||||

| Pipe wall thickness range | 0.5-1.2MM | ||||

| Minimum cutting length | 30mm(Saw blade cutting); or 60mm(Chipless ring cutting) | ||||

| Cutting accuracy | ±0.5mm | ||||

| Cut off motor power | 1.1KW (Saw blade cutting); or 0.55kw(Chipless ring cutting) | ||||

| Feed servo motor power | 1.5KW | ||||

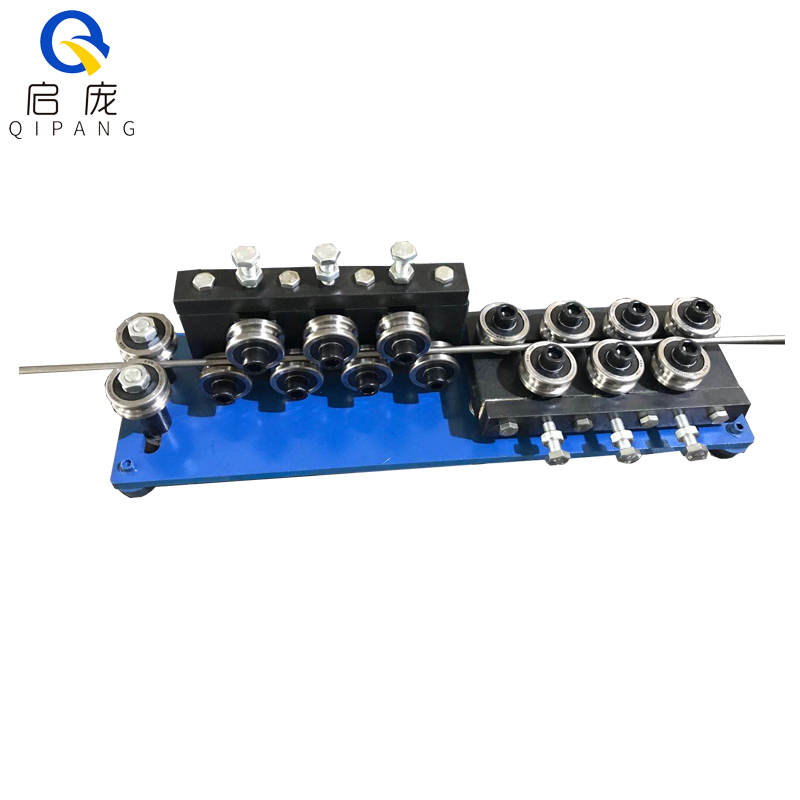

| Straightening part | 9+9 wheels (horizontal + vertical) nylon wheels/steel wheels optional | ||||

| Operation mode | Automatic | ||||

| Operating system | touch screen operation + PLC control | ||||

| Input voltage | 380 volts, three-phase, 50 Hz | ||||

| Air source pressure | 0.4-0.6Mpa | ||||