Servo-Driven PLC Double-Head Coil Pipe Straightening and Cutting Equipment for Copper Aluminum Tube Processing

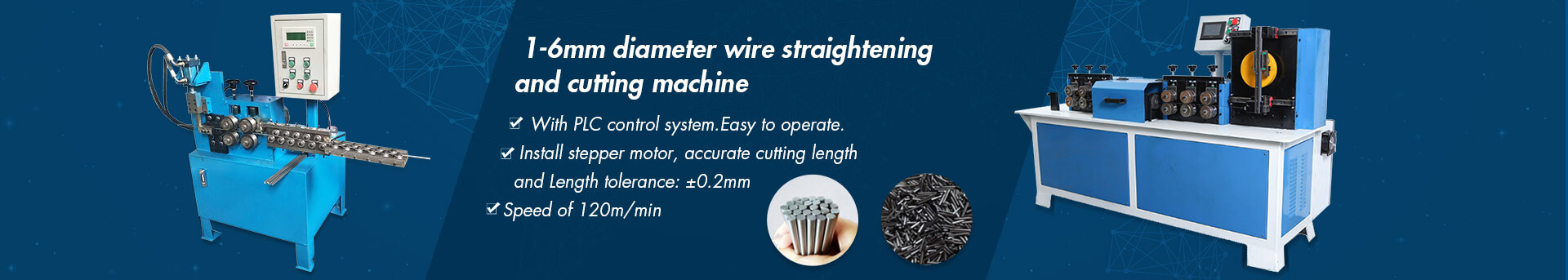

Shanghai Qipang mainly focuses on the production of : CNC Straightener and Cutter Machine, electric straighteners, manual straighteners, and traction feeding systems.

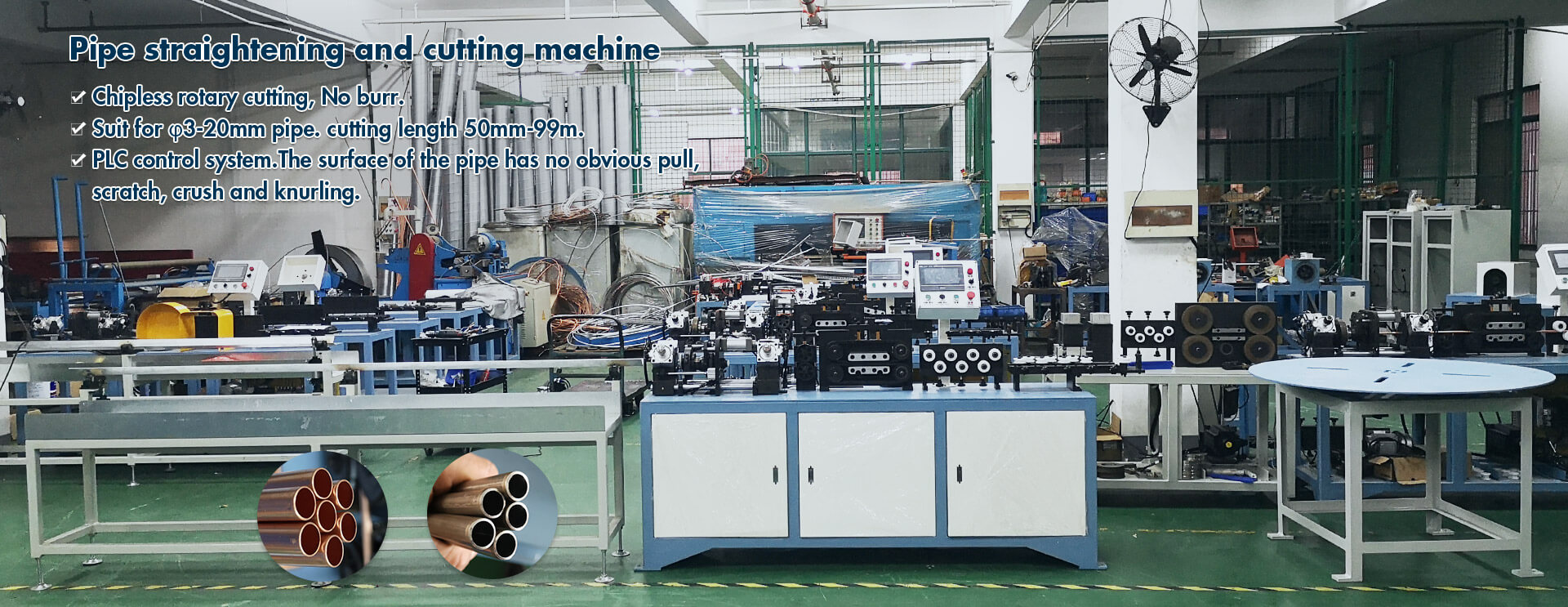

Double-Head Coil Pipe Straightening and Cutting Equipments are suitable for various pipe materials, such as copper pipes, aluminum pipes, stainless steel pipes, Bondi pipes, and iron pipes, and are applicable to both round and square pipes.

Double-Head Coil Pipe Straightening and Cutting Equipments are suitable for pipe outer diameters of : 4 mm, 6.35 mm, 8 mm, 9.52 mm, 12.7 mm, 15.88 mm( 5/32",1/4",5/16",3/8",1/2",5/8").

Equipment Name and Process: Double-Head Coil Pipe Straightening and Cutting Equipment for Soft Stainless Steel Pipes

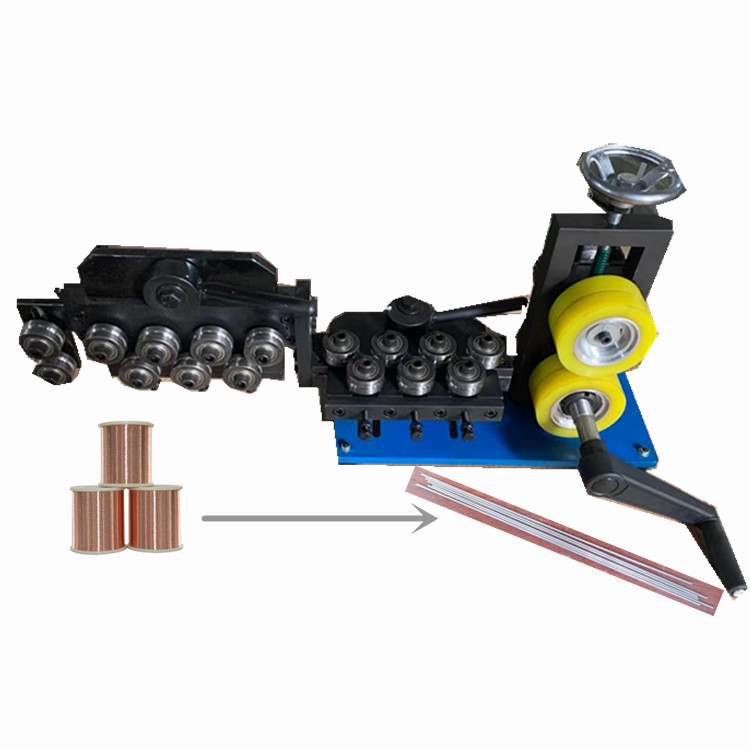

The machine uses the straightening mechanism for cutting pipes of different diameters;This Aluminum Pipe Straightening Cutting Machine employs servo and ball screw feeding to ensure accurate material length; Pipe cutting methods: saw blade cutting, resulting in no shrinkage or deformation at the end face; or ring cutter cutting, resulting in no burrs at the end face. High speed and efficiency.

The complete set Double-Head Coil Pipe Straightening and Cutting Equipment includes:

1. Pay-off rack (multiple styles available)--Optional

2. CNC straightening and cutting machine (main unit)

3. Pneumatic tilting receiving rack (standard 1.2-meter length selectable)--Optional

Note: Unless otherwise stated, the quote usually only includes the main unit.

Technical Parameter | |||||

| Device model | Dual-head with one program (Straighten and cut two pieces at once, both of the same length) | ||||

| Applicable pipes | copper,aluminum,stainless steel,bondi pipes | ||||

| Pipe processing range | Φ4-Φ16 (Φ5/32''- 5/8'') | ||||

| Minimum cutting length | 30mm(Saw blade cutting); or 60mm(Chipless ring cutting) | ||||

| Cutting accuracy | ±0.5mm | ||||

| Wall thickness range | 0.5-1.2MM | ||||

| Cut off motor power | 1.1kw (Saw blade cutting); or 0.55kw(Chipless ring cutting) | ||||

| Feed servo motor power | 1.5kw | ||||

| Operating system | touch screen + PLC control | ||||

| Operation mode | Automatic | ||||

| Straightening part | 7+9 wheels (horizontal + vertical) nylon /steel wheels optional | ||||

| Input voltage | 380 volts, three-phase, 50 Hz | ||||

| Air source pressure | 0.4-0.6Mpa | ||||

Double-Head Coil Pipe Straightening and Cutting Equipment Image: